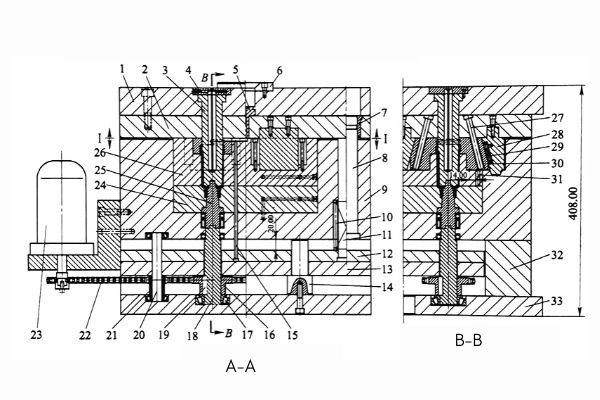

The servo unscrewing devices can be constructed depending on the requirements with one 1 or two 2 gearbox levels and is based on the following parameters. Cavity spacing and arrangement of the cavities.

Auto Unscrewing Injection Mold Design Solutions Upmold

This keeps the pressure on the underside of the part so the teeth on engaged to keep the cap from rotating with the unscrewing core.

. This video is about an automatic unscrew thread injection mold. However the ejection forces increase contrary in the area of. Unscrewing molds consist of a rack motor or hydraulic cylinder and a gear rack.

Also referred to as unscrewing moulds. 1 General Introduction This handbook is to be used in conjunction with the prod-uct data for specific DuPont Engineering Thermoplastic resins DELRIN acetal resins ZYTEL nylon resins inclu- ding glass reinforced MINLON engineering thermoplastic resins and CRASTIN PBT and RYNITE PET thermo- plastic polyester resins. The articles will begin in the May issue.

Unscrewing cores injection moldingunscrewing injection mold designautomatic unscrewing mould buildingautomatic screw injection moldingautomatic unscrew moldi. Tion molder mold designer and mold builder. Standardized System for Molding Internal Threads Metric-rack design Off -the-shelf replacement parts Simplifies mold design Applicable to different design styles Technical and application support Rack sized to provide maximum stroke lengths Hydraulic Unscrewing Device AT P.

To avoid thread damage such parts must be unscrewed from the mold. Flip top cap product info. 204500X204500X169125 Part weight1325kg Cavity weight14000kg.

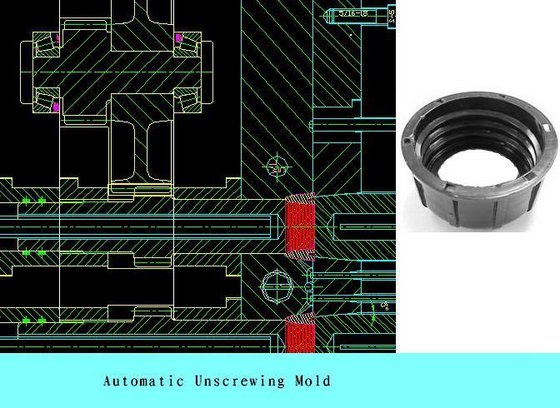

Thread size and length and thus maximum breakaway torque. We design internal and external threads in custom plastic parts during plastic molding process through unscrewing molds. Unscrewing Mold Design for Protector.

16s Check following mold testing video. This section provides general guidelines for the design of a good efficient mold for making. Part size200000X200000X165000 Shrinkage rate10225 Cavitation size.

Unscrewing injection molding design of mould tool At the place that the mould tool opens prior to an unscrewing operation the piece will be kept on the shifting part of the mould tool. Mold Build Assembly 42-45 6. Weld lines occur when flow fronts travelling in opposite directions meet.

5 Product and Mold Design 62 Proper design of the injection mold is crucial to producing a functional plastic component. Quick Reference Checklists 59-64 8. Choosing unscrewing components for your molds shortens leadtimes reduces component costs and decreases cycle times.

The informa tion contained in the guide lines will maximize the molds cycle time and improve part quality with the use of copper alloys in the mold. These information packed Injection Mold Design Guidelines are being developed and generated by The Copper. Automatic unscrew thread injection mold is used for plastic parts with internal thread.

Hydraulic Cylinder components associated with Unscrewing mold applications. 2 tips hot runner to submarine gate mold dimension. This amalgamation is important for facilitating the manufacturing procedure and helping the cavities when they need to vent out.

In cases like this it is very important to shape the. 49 6062 80933-0 Fax. Design of the Automatic Unscrewing Mold.

The stripper plate will need an outside mechanism to cam the stripper plate in at the same rate as the thread pitch. Mold design has great impact on productivity and part quality directly affecting the profitability of the molding operation. Microsoft PowerPoint - Mould Design 2011bppt.

Unscrewing mold design with Rotary Motor driver. Unscrewing mold design with Sliders. SAM Servo Unscrewing Device Multi 16 cav.

Unscrewing Injection Mould Design Solutions Unscrewing Molding Manufacturer with Servo Motor Hydraulic Motor Hydrau Model NO. The design part of the mold is movable in nature and undertakes the shape of a mosaic. EW0490 Shaping Mode Injection Mould Surface Finish Process Vdi Texture Mould Cavity Single Cavity Plastic Material PE Process Combination Type Single-Process Mode Application Car Household Appliances Furniture Commodity Electronic.

Unscrewing molding is a unique injection molding process with molding technology. Maintenance Repair 46-58 7. Gating locations A consequence of gating a cup shaped component from the side is the formation of weld lines.

36grams 26mm neck dia. People are challenging traditional methods. Internal threads can be on collapsible cores or in unscrewing molds.

Complex tooling and high maintenance molds Game has changed Tough economic times. Standardized System for Molding Internal Threads Metric-rack design Off -the-shelf replacement parts Simplifies mold design Applicable to different design styles Technical and application support Rack sized to provide maximum stroke lengths Hydraulic Unscrewing Device AT P. 0800 301 060 F.

Hydraulic cylinder drive the rack structure to realize flip top. 0800 301 060 F. D-M-E Company provides these application notes as a suggested method based upon prior applications and experience.

Although moldmakers are always on the lookout for ways to shorten leadtimes while still maintaining quality dealing with external components and hydraulics can further complicate the mold design and build process especially. Mold Design 29-41 5. We are unscrewing molds company in China provide free Tooling Quoting service.

In injection molding the ejection forces decrease when the surface roughness of mold decreases. This leaves a visible trace on the surface of the. SAH Servo Unscrewing Half Market.

D-M-E Company assumes no liability for the construction or design of said mold or. The mold remains in a moveable situation for machining purposes. Unscrewing mold design pdf 此幻灯需要JavaScript持 product name.

Cavitation Size204487X204487X179375 Cavity volume24kg Part Size. External threads can be parted and molded in both mold halves.

Automatic Unscrew Thread Injection Mold For Pipe Fitting

Auto Unscrewing Injection Mold Design Solutions Upmold

Injection Mold Design Service Included In Our Injection Mold Manufacturing Business Experienced With All International Standards Molding Injection Manufacturer Tsy Molding Limited Specializes In Overmold Unscrewing Mold Precision Mold Injection

Automatic Unscrewing Mold Plastic Mold Id 6203765 Product Details View Automatic Unscrewing Mold Plastic Mold From Leeon Industry Development Limited Ec21

Injection Mold Design Service Included In Our Injection Mold Manufacturing Business Experienced With All International Standards Molding Injection Manufacturer Tsy Molding Limited Specializes In Overmold Unscrewing Mold Precision Mold Injection

Unscrewing Injection Mold Design With Sliders Study Case Upmold

Unscrewing Plastic Mold Design With Rotary Driving Case Upmold

Pdf Demolding Moment Calculation For Injected Parts With Internal Saw Thread

0 comments

Post a Comment