Appropriate apparatus is developed for holding the blank in place during forming and cooling the closed mold post. At the same time our proprietary post-top globes refractors and spheres have been lighting the way in municipalities throughout the country.

Designing From The Design Guide Chapter 2 Ray Products

Mold refurbishement and repair.

. Understanding Blow Molding Extrusion Blow Molding STEP 1 Parison is extruded into mold STEP 2 Blow mold seals around parison STEP 3 Parison is inflated with air STEP 4 Parison cools and mold opens Injection blow molding is the least commonly used method and is used to manufacture small. Packaging is the science art and technology of enclosing or protecting products for distribution storage sale and use. In this process PLA sheet is heated to soften the polymer forced either pneumatic andor mechanically against the mold allowed to cool removed from the mold and then trimmed.

The authors emphasized that this technique overcomes constraints in the characteristics of 3D-printed parts allowing direct stereolithography printing of molds for use in both academic and. Mold closes and the parison is inflated until it takes the shape of the mold cavity. Packaging also refers to the process of designing evaluating and producing packages.

Has been recognized as an industry leader in custom rotational molding thermoforming and fabrication. Full PDF Package Download Full PDF Package. We partner with our customers world class technology partners to design manufacture and deliver best value solutions.

Designing manufacturing delivering packaging. A short summary of this paper. Download Full PDF Package.

The thermoforming simulations and mechanical performance are experimentally validated by first fabricating a 2 mm thick composite hat structure using thermoforming process and then performing a 3-point bend test as well as a dynamic impact test. Packaging can be described as a coordinated system of preparing goods for transport warehousing logistics sale and end usePackaging contains protects preserves. The authors demonstrated that by combining materials and mold design the service life of the as-prepared injection and vacuum casting mold could be significantly increased.

16 Full PDFs related to this paper. Heating of PLA sheet for thermoforming is generally achieved by infrared red IR radiation from heater elements. Quick-Change Sets EOATs Service.

Product and label design. Each polymer has an optimum IR absorbance frequency in the IR region. Operating 12 manufacturing facilities in Canada US Poland to serve the.

Since 1946 Formed Plastics Inc. Typical values for uncolored products Please note that all processing data stated are only indicative and may vary depending on the individual processing complexities. AWWA M55 2006 PE Pipe Design and Installation.

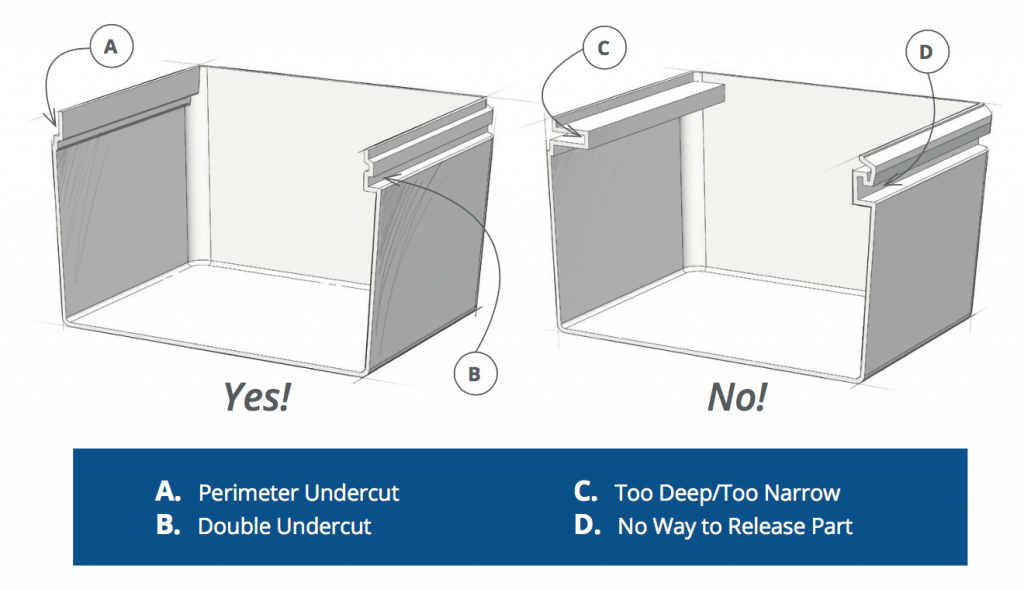

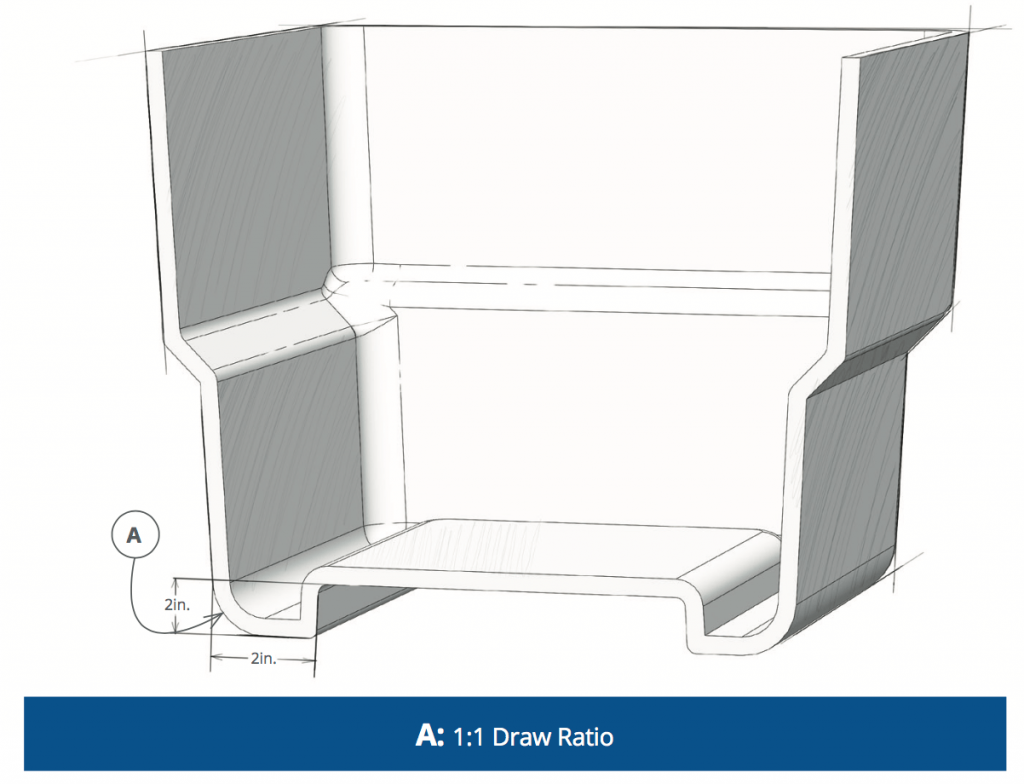

Mold Temperature Range -F. Our businesses fall into 2 categories Plastics Processing and Mold Tooling. Normally draft angles are present in the design of the mold a.

Vacuum forming is a simplified version of thermoforming where a sheet of plastic is heated to a forming temperature stretched onto a single-surface mold and forced against the mold by a vacuumThis process can be used to form plastic into permanent objects such as turnpike signs and protective covers.

Designing From The Design Guide Chapter 2 Ray Products

Pdf Design For Additive Manufacturing Thermoforming Mold Optimization Via Conformal Cooling Channel Technology

0 comments

Post a Comment